Ho tlanya tšepe e thata Lipompo tse ntle tsa carbide bakeng sa lipompo tsa tšepe tse thata tsa M, UNC, BSP

- Tlhaloso

Indasteri ea hlobo le ea die hangata e tlameha ho tlanya lisebelisoa tse thata, tse hlokang lipompo tse khethehileng ho sebetsana le litšepe tse thata haholo.

Thepa ea mochini oa carbide oa OPT le sete ea letsoho ea carbide e etselitsoe ho tlanya tšepe e thata le tšepe e thata haholo ho fihla ho 63 HRC.

Tekanyetso ea ISO, maemo a JIS, DIN standard carbide theipi tsohle tse fumanehang 'me li ka etsoa ka nako e khutšoane ea ho etella pele.

OPT e ikemiselitse ho etsa likhoele liindastering tse fapaneng, ho latela ts'ebeliso ea bareki e ts'oanang le tharollo ea machining, re boetse re fana ka li-drill tsa premium carbide le reamers bakeng sa machining tšepe e thata.

Rea u amohela ho ikopanya le rona ho buisana ka morero oa hau.

- Tšebeliso e tloaelehileng

Tool Materail: Ha ho nahanoa ka khanyetso ea ho roala le ho hanyetsa phello, lisebelisoa tsa "tungsten carbide" tse nang le boima bo lekaneng le boima bo lekaneng li sebelisoa ho netefatsa ho tšoarella ha lipompo tsa carbide.

Geometry: Ho eketsa boima le ho thibela ho robeha ha moeli, li-angles tse khethehileng tsa rake li entsoe

Bolelele ba Chamfer: Ha ho nahanoa ka botsitso le bophelo ba lisebelisoa, bolelele ba sehiloeng ka chamfer hangata ke meno a 4-5.

Mochini: Etsa tlhahiso ea ho sebelisa sesebelisoa sa mochini se nang le vibrate e tlase le bokhoni ba ho khetha sekhahla se loketseng sa phepelo ho fihlela ho thepha ho tsitsitseng.

Sekoti se ka tlase: Cheka sekoti se ka tlase se seholo ka hohle kamoo ho ka khonehang ka har'a mamello ea khoele hobane e thusa ho fokotsa mojaro oa torque le ho tlanya ho fetoha bophelo bo bolelele.

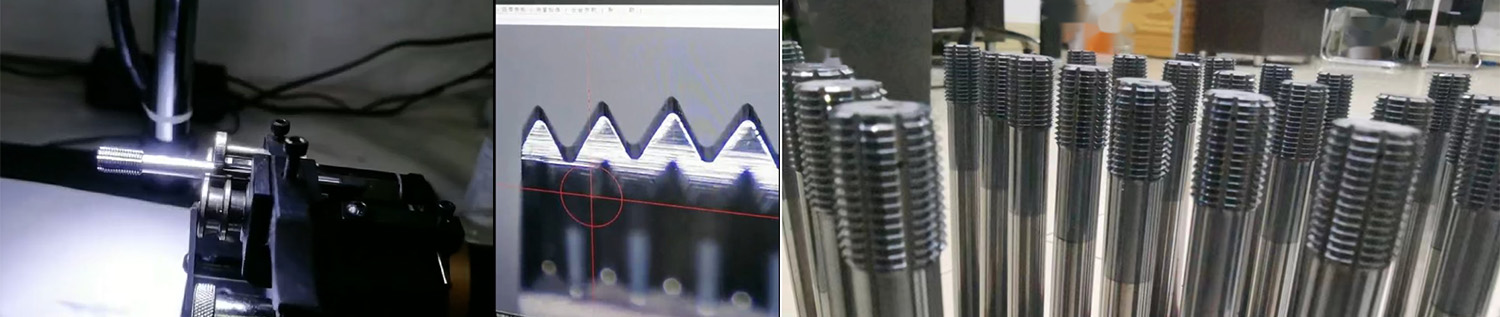

Ho hlahloba le ho bonts'a

Pele o reka, ka kopo ikopanye le litšebeletso tsa rona tsa bareki ba pele ho thekiso:

1. Lisebelisoa tsa workpiece

2. Hore na sehlahisoa se tšoaroa ka holim'a metsi ka mor'a ho sebetsa

3. Litlhoko tsa ho nepahala, boholo ba go gauge le ho se be gauge.