Mochini oa carbide o tlanya Spiral flute Tlanya Lipompo tse tiileng tsa carbide bakeng sa aluminium

Likaroloana:

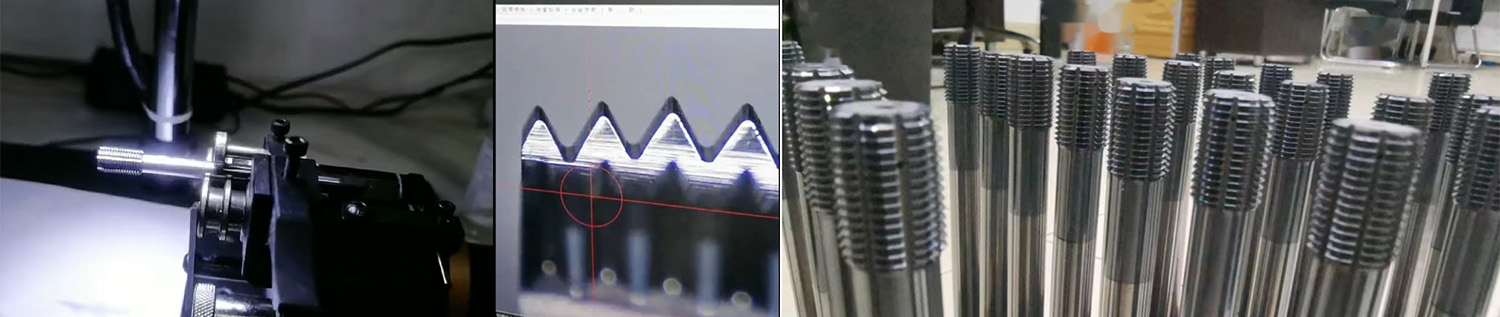

1. Superior Chip Vacuation: Ho thibela chip jamming, le ho tsamaisa mokhoa o boreleli oa machining.

2. Bophelo bo Atolositsoeng ba Sesebelisoa: Ka lebaka la thepa ea premium carbide, lipompo tsa spiral carbide li bonts'a khanyetso e ikhethang ea ho apara, e bakang bophelo bo bolelele ba lisebelisoa le ho fokotsa litšenyehelo tsa ho fetola lisebelisoa.

3. Qetello ea Bokaholimo bo Ntlafetseng: Geometry e nepahetseng ea ho itšeha ea lipompo tsa spiral carbide e lumella machining a hloekileng le a nepahetseng, e leng se fellang ka ho ntlafala ha bokaholimo le ho nepahala ha likarolo tsa aluminium tse entsoeng ka mechine.

4. Ho Eketseha ha Machining Speed: Ka ts'ebetso e ntlafalitsoeng ea ho tlosoa ha chip le ho senya mocheso ho fanoang ke lipompo tsa spiral carbide, lebelo le phahameng la ho itšeha le ka finyelloa ntle le ho sekisetsa bophelo ba sesebelisoa kapa botšepehi ba workpiece.

Tšebeliso e tloaelehileng 02

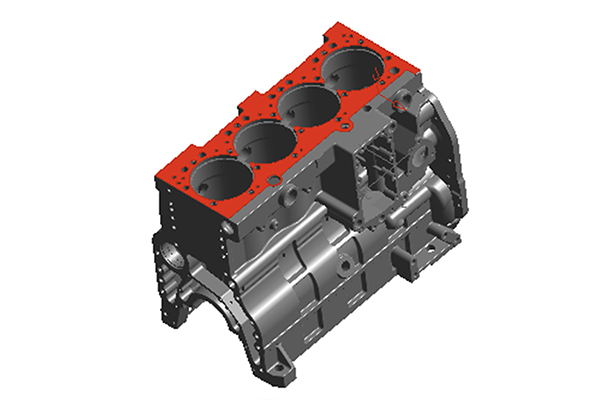

Indasteri ea Sefofane:Lisebelisoa tsa aluminium li bapala karolo ea bohlokoa tlhahisong ea lifofane, 'me lipompo tsa spiral carbide li bohlokoa bakeng sa ho theha likarolo tse nepahetseng tsa lienjine tsa sefofane, mapheo a mapheo le liforeimi.

Tšebeliso e tloaelehileng 03

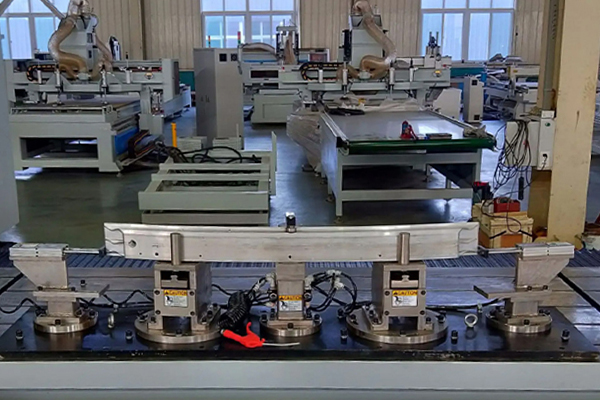

Indasteri ea Elektronike:Ka tlhokahalo e ntseng e eketseha ea lisebelisoa tsa elektroniki tse bobebe, aluminium e sebelisoa khafetsa tlhahisong ea li-casings le lisinki tsa mocheso.Lipompo tsa Spiral carbide li netefatsa mochini o nepahetseng le likhoele tse ts'oanang lits'ebetsong tsena.