Ha re tobetsa likhoele, ho na le mefuta e mengata ea lipompo tseo u ka khethang ho tsona.Re ka li khetha joang?Joalo ka ho tlanya tšepe e thata, ho tlanya tšepe e entsoeng ka tšepe, kapa ho tlanya aluminiamo, re lokela ho etsa joang?

E, kaofela ha tsona li sebelisetsoa ho tlanya likhoele, empa ho khetha pompo e loketseng ho hloka ho utloisisa mosebetsi oa hau le maemo a sebetsang, joalo ka thepa ea workpiece e ntseng e sebetsoa, boholo le botebo ba lesoba le ka tlaase la khoele, le hore na ho na le tšitiso, ka ho etsa hore ts'ebetso ea hau e sebetse hantle le ho sebetsa hantle.

Karolelano e arotsoe haholo ka mekhahlelo e 'meli e latelang ho latela ponahalo le sebopeho:

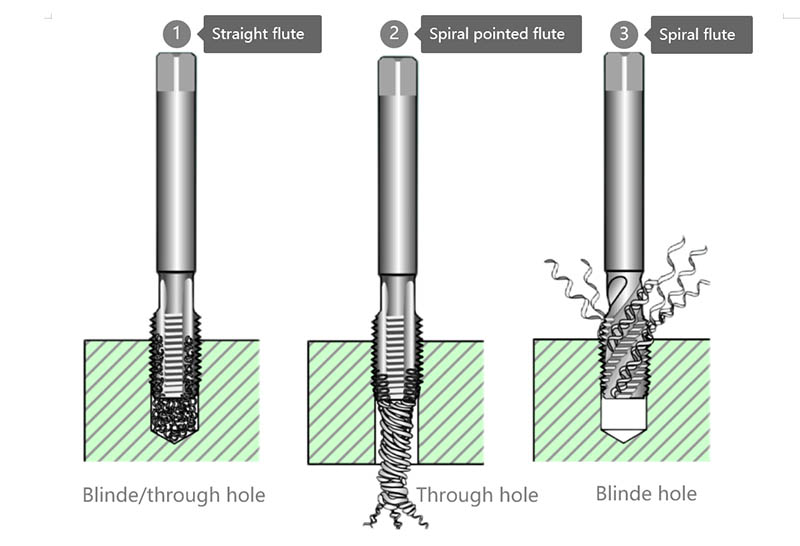

1.Tlanya e otlolohileng ya lekolilo: e sebelisetsoang ho sebetsa le masoba a foufetseng.Li-chips tsa tšepe li teng ka har'a tap groove, 'me boleng ba khoele e sebetsitsoeng ha bo holimo.E sebelisoa haholo bakeng sa ho sebetsana le lisebelisoa tse khutšoane tsa chip, joalo ka tšepe ea grey cast.

2.Theipi e nchocho ka Spiral: hangata e sebelisoa feela ka mekoting, ka karolelano ea bolelele ho isa ho bophara ho fihla ho 3D~3.5D, lisebelisoa tsa tšepe tse lahleloang ka tlase, torque e tlase e sehiloeng, le boleng bo holimo ba khoele e sebelitsoeng.E boetse e tsejoa e le edge angle tap kapa tip tap.

Ha u itšeha, hoa hlokahala ho etsa bonnete ba hore likarolo tsohle tsa ho itšeha li kenelletse, ho seng joalo ho robeha ha leino ho ka etsahala.

3.Mopitla oa lekolilo: e sebelisetsoa ho sebetsana le lesoba le foufetseng le botebo ba sekoti bo ka tlaase ho kapa bo lekanang le 3D.Li-chips tsa tšepe li ntšoa haufi le spiral groove, e leng se hlahisang boleng bo holimo ba khoele.

Thepa ea 10-20 ° spiral angle e ka sebetsa botebo ba khoele ho fihla ho 2D;Thepa ea 28-40 ° spiral angle tap e ka sebetsana le botebo ba khoele ho fihla ho 3D;The 50 ° spiral angle tap e ka sebetsana le botebo ba khoele ho fihla ho 3.5D (boemo bo khethehileng ba ho sebetsa 4D).

Ka linako tse ling (lisebelisoa tse thata, mekotla e meholo ea meno, joalo-joalo), e le ho fumana matla a betere a leino, lipompo tsa lekolilo li sebelisoa ho sebetsa ka masoba.

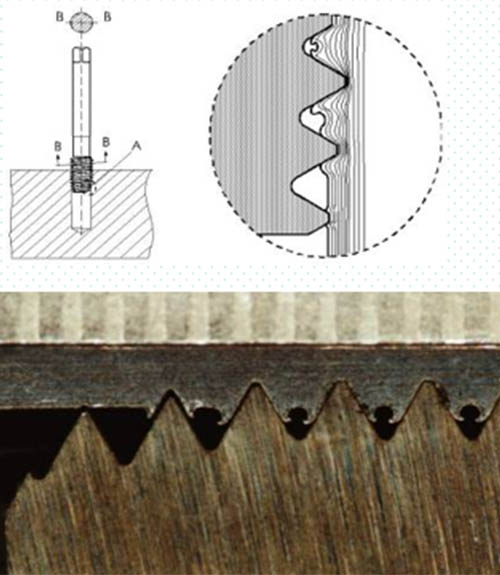

E ka sebelisoa bakeng sa ho sebetsa ka likoti le masoba a foufetseng, ho etsa libopeho tsa meno ka ho senyeha ha polasetiki ea thepa, 'me e ka sebelisoa feela bakeng sa ho sebetsana le thepa ea polasetiki.

Boreleli ba holim'a khoele e fetisitsoeng ka pompo ea foromo bo nepahetse, likhoele tsa tšepe tsa khoele ha li robehe, 'me ho thehoa lesela le thata le batang holim'a metsi, le ka ntlafatsang matla le ho apara ho hanyetsa khoele.

Har'a lipompo tsohle, likhoele tsa ho etsa likhoele ke tse phethahetseng ka ho fetesisa, tse nang le matla a phahameng ka ho fetesisa le sekhahla sa ho tšoaneleha ha khoele, ha feela bophara ba lesoba le tlase bo loketse.

Litšobotsi tsa mantlha:

1. Sebelisa deformation ea polasetiki ea workpiece ho sebetsa likhoele;

2. Theipi e na le sebaka se seholo sa li-cross-sectional, matla a phahameng, 'me ha e robehe habonolo;

3. Lebelo la ho itšeha le ka ba le phahameng ho feta pompong ea ho itšeha, 'me tlhahiso e boetse e eketseha ho latela;

4. Ka lebaka la ts'ebetso e batang ea li-extrusion, thepa ea mochine ea khoele e entsoeng ka holimo e ntlafatsoa, ho hlaka ho holimo ho phahame, 'me matla a khoele, ho hanyetsa ho roala, le ho hanyetsa kutu hoa ntlafatsoa;

5. Ts'ebetso ea mahala ea Chip.

Mefokolo ea eona ke:

E ka sebelisoa feela bakeng sa ho lokisa lisebelisoa tsa polasetiki;

Ho na le mefuta e 'meli ea meralo:

1. The non oil groove form pompong e sebelisoa feela bakeng sa boemo ba ho sebetsa ea foufetseng lesoba paatsepama phaella moo;

Lipompo tse 2 tse etsang li-groove li loketse maemo ohle a ts'ebetso, empa hangata lipompo tse nyane tsa bophara ha li entsoe ka li-groove tsa oli ka lebaka la mathata a tlhahiso.

Nako ea poso: Oct-11-2023