Thepa ea Carbide bakeng sa tšepe e thata e otlolohileng lekolilo Metric tap, UNC tap

- Tlhaloso ea Sehlahisoa

Lipompo tse entsoeng ka thepa ea HSSE kapa HSSE-PM li loketse feela lisebelisoa tsa ho sebetsa tse nang le boima bo ka tlase ho HRC49.Ka hona, bakeng sa li-workpieces tse kantle ho mofuta ona oa boima, pompo ea carbide e fetoha khetho e ratoang ea ho sebetsa.

OPT carbide tap bakeng sa tšepe e thata e nang le li-germery tsa eona tse khethehileng tsa li-flute le li-angles tsa eona tse khethehileng tsa mochini le li-angles tsa liphallelo li etsa hore tšepe e sehang e tšoarelle nako e telele, e sebetsa ho hardpiece ea HRC55-63.

TiCN kapa ALTiN e sebelisoa ho matlafatsa boima ba 'mele le ho hanyetsa ho roala ho ntlafatsa bophelo ba lisebelisoa.

Ho latela kopo ea mosebelisi oa ho qetela, moetapele oa foromo ea Chamfer hangata e ka ba likhoele tse 2-3 kapa likhoele tsa 4-5, hangata e tla sebelisoa ho machining CNC, sete ea theipi e fumaneha hape bakeng sa tšebeliso ea manuel.

- Tšebeliso e tloaelehileng

Lilemong tsa morao tjena, tlhoko ea machining e nepahetseng ea likarolo tse entsoeng ka tšepe e thata e eketsehile haholo.Tšebeliso e ntseng e eketseha ea litšepe tse thata liindastering tse kang tsa makoloi, sepakapaka, le ho etsa thepa e hloka hore ho sebelisoe lisebelisoa tse khethehileng tse ka sebetsanang le maemo a thata a phahameng.Lipompo tsa carbide tse etselitsoeng ka ho khetheha lisebelisoa tsa tšepe tse thata li fetohile tsa bohlokoa haholo tabeng ena.

Ho bohlokoa ho khetha pompo e nepahetseng ea carbide bakeng sa sesebelisoa se seng le se seng se ikhethileng.

OPT e ikemiselitse ho etsa likhoele liindastering tse fapaneng, ho latela ts'ebeliso ea bareki e ts'oanang le tharollo ea machining, ho tlisetsa bareki liphetho tse ntle tsa ts'ebetso le katleho ea tlhahiso.

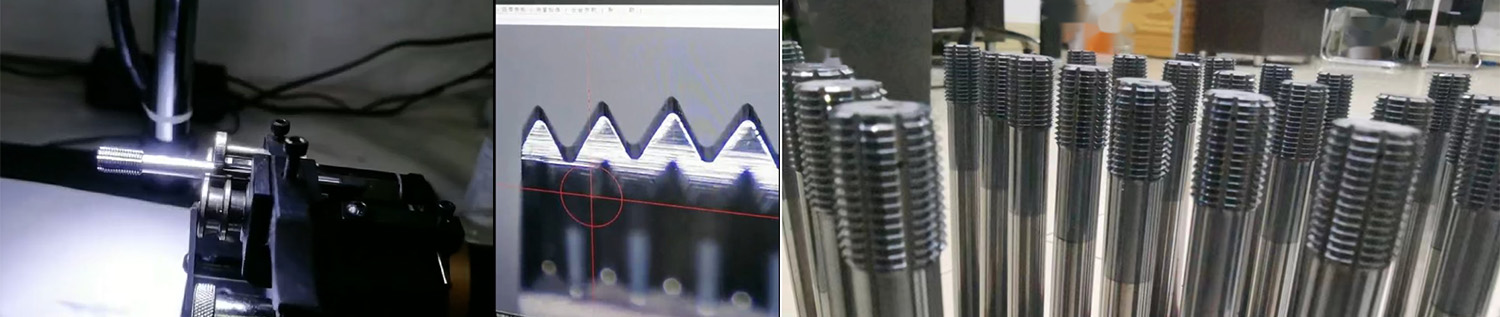

Ho hlahloba le ho bonts'a

Pele o reka, ka kopo ikopanye le litšebeletso tsa rona tsa bareki ba pele ho thekiso:

1. Lisebelisoa tsa workpiece

2. Hore na sehlahisoa se tšoaroa ka holim'a metsi ka mor'a ho sebetsa

3. Litlhoko tsa ho nepahala, boholo ba go gauge le ho se be gauge.