PCD Turning Grooving Insets PCD external grooving e kenya lisebelisoa tse kholo tsa daemane tse fetolang groove.

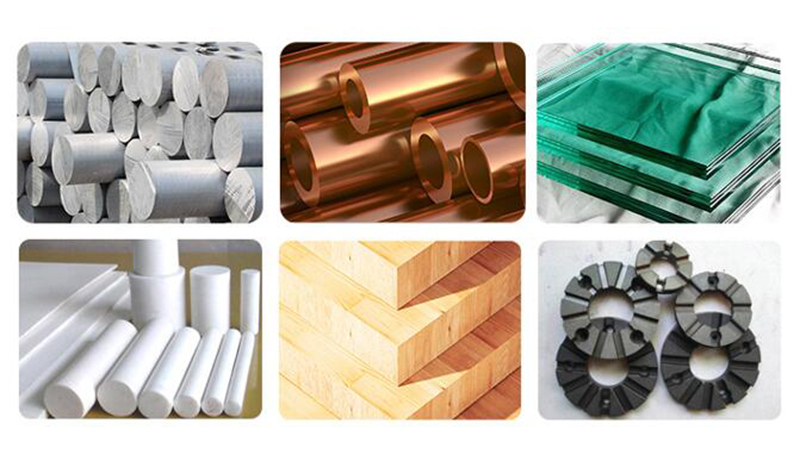

Ho khaola lisebelisoa tse ngata

E loketse ho sebetsana le litšepe tse se nang ferrous tse kang aluminium le li-alloys tsa aluminium, li-alloys tsa koporo le tsa koporo, titanium, magnesium, zinki le loto.Fiber ea khalase, fiber ea carbon, polasetiki e matlafalitsoeng le lisebelisoa tse ling tseo e seng tsa tšepe.

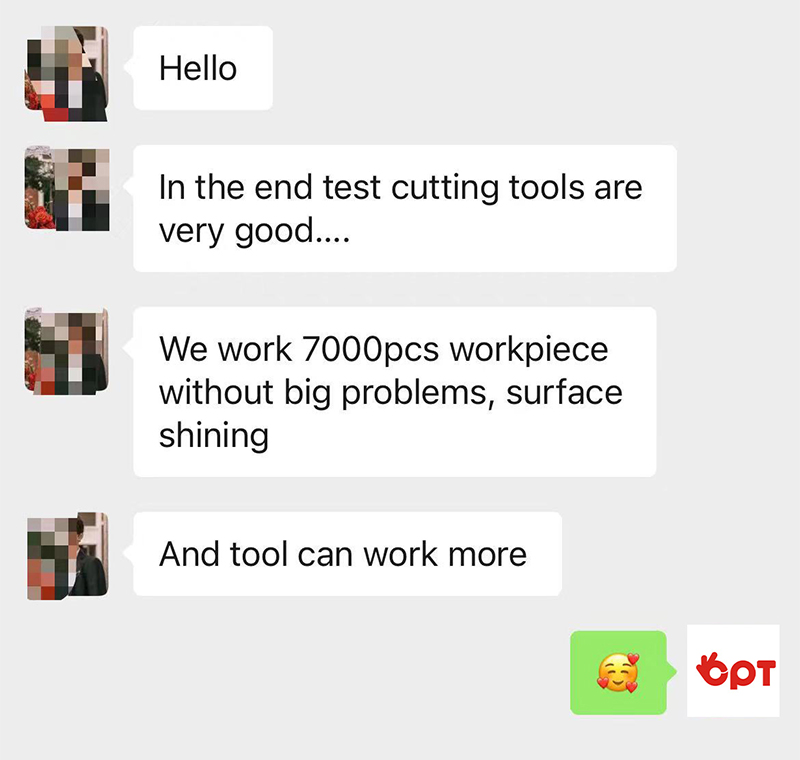

Melemo ea lihlahisoa

Ntlafatso ea tekheniki, flatness e ntle

Hobane coefficient ea likhohlano e fokotsehile, khanyetso ea ho itšeha e fokotsehile mme ho itšeha ho hlabang hoa phethahala.Moeli o khathollang o na le khanyetso e phahameng haholo ea ho roala le ho tiea, ho thatafala ho phahameng, conductivity e phahameng ea mocheso, le coefficient e tlase ea katoloso ea mocheso.Mohatla oa thipa oa vacuum o tiile ebile oa tšepahala, 'me thipa ha e qhomele.

PCD piston bits Theknoloji e tsoetseng pele, e bohale ebile e manganga

Kakaretso e thata ea lehare e matla, ho itšeha ho matla haholoanyane, 'me bophelo ba tšebeletso bo telele Lehare le bohale le ho hanyetsa ho nyane.Mokhoa o ntlafalitsoeng oa ho itšeha o etsa hore seha se tsitsa le ho tlosoa ha chip kapele.Sekhahla se bohale ebile se boreleli, se sa senyehe ebile se thibela mocheso

Ho seha ka boreledi ntle le ho kgomarela sesebedisoa

Lithako tsa tšepe ha li itlotse ka lebota la groove, boreleli bo ntlafatsoa ka tlhaho, 'me ha ho bonolo ho khomarela sesebelisoa.E na le phello e ntle ea ho senya chip le phello ea ho tlosa chip, 'me e ntlafatsa bophelo ba tšebeletso ea sesebelisoa.

Sesebelisoa sa rona sa PCD grooving bakeng sa piston se na le khetho e thata ea thepa

Taemane ea boleng bo phahameng ea maiketsetso e sebelisoa ho netefatsa bophelo ba ts'ebeletso ea sesebelisoa.Sesebelisoa se bohale ebile ha se sebetse, se na le boima bo phahameng, matla a khatello e phahameng, conductivity e matla ea mocheso le ho hanyetsa ho apara.Lisebelisoa tsa ho sebetsa li ka finyella phello ea seipone.Lebelo la ho itšeha ka potlako, sekhahla se phahameng sa deburring ea thepa ea workpiece.

External Grooving Tool sebelisa High quality diamond maiketsetso, sebetsa ntle le deformation

E hloekisoa ka ho khetha taemane ea boleng bo holimo.Mocheso o sehang o bonolo ho senya.Mocheso oa ho itšeha oa lehare o tlase.Mochine o sebetsang hantle haholo ha o holofale, ha o senyehe, 'me o na le bophelo bo bolelele ba ts'ebeletso.

Sesebelisoa sa PCD Piston Ho sebetsa hantle le ho sebetsa hantle

Moralo o utloahalang oa ho tlosa li-chips, o kopantsoeng le ho chorisa ka mokhoa o nepahetseng haholo oa peripheral, o etsa hore lehare le be bohale, ho be bonolo ho sebetsa, le ho sebetsa hantle haholoanyane ha ho sebetsoa lisebelisoa .

| Mofuta | Boholo(mm) | Kereiti | ||||||||

| L | QI.C | S | d | r | OPT850 | OPT005 | OPTO10 | OPT302 | ||

| MGMN | 200-02-L | 2.0 | 0.2 | 20 | 1.7 | - | ★ | |||

| 300-02-L | 2.0 | 0.2 | 20 | 2.3 | - | ★ | ||||

| 400-02-L | 4.0 | 0.2 | 20 | 3.3 | - | ★ | ||||

| 500-03-L | 5.0 | 0.3 | 25 | 4.1 | - | ★ | ||||

| 600-03-L | 6.0 | 0.3 | 25 | 5.1 | - | ★ | ||||