Ke phapang efe pakeng tsa HSS milling cutters le Carbide milling cutters mabapi le thepa, sebopeho le ts'ebetso?Ke maemong afe a machining a lokelang ho sebelisoa lisebelisoa tsa HSS, 'me lisebelisoa tsa Carbide li lokela ho sebelisoa maemong afe?

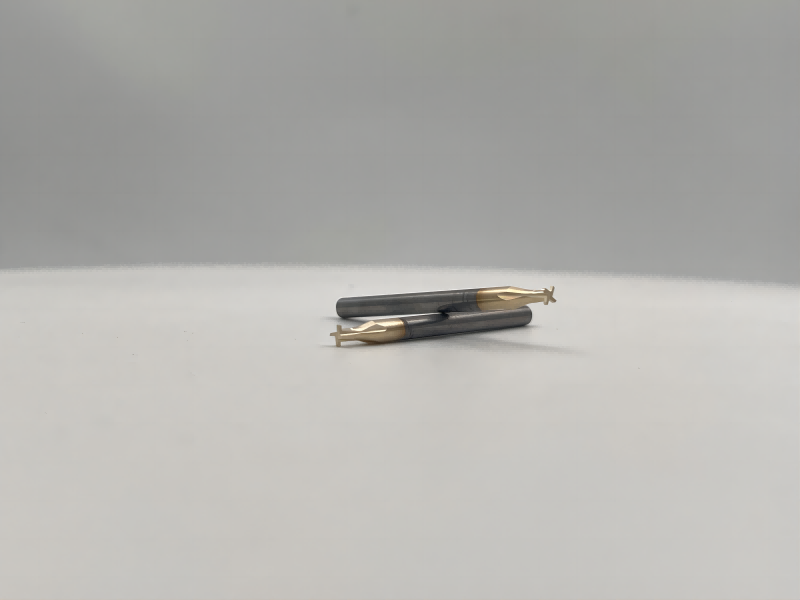

1. Phapang pakeng tsa HSS End Mill le Tungsten Carbide End Mill

1. Phapang ea thepa.

HSS End Mill e entsoe ka litšepe tse lebelo le holimo, hangata li entsoe ka thepa ea M42, e nang le vanadium e sa feteng 1% le cobalt ea 8%.

Carbide End Mill ke sesebelisoa sa CNC se entsoeng ke Tungsten Carbide.

2. Liphapang tsa ts'ebetso ea ts'ebetso.

Lisebelisoa tsa ho itšeha tsa HSS li na le boima ba mocheso oa kamore ea 62-70HRC, ha lisebelisoa tsa ho itšeha tsa carbide li na le boima ba mocheso oa kamore ea 89-94HRC.Ho hanyetsa mocheso oa holim'a sesebelisoa ho fihla ho 1000 ℃, 'me lebelo la ho itšeha la carbide le ka eketsoa ka 50-100% ha le bapisoa le HSS.Ho tšoarella ha sesebelisoa ho ka ntlafatsoa ka makhetlo a 2-10;Ha ho bapisoa le lisebelisoa tsa ho itšeha tsa HSS, lisebelisoa tsa ho itšeha li-carbide li loketse haholo bakeng sa ts'ebetso e potlakileng, e sebetsang hantle le e phahameng ea mocheso.

lisebelisoa tsa ho seha carbideSebaka se phahameng sa ho qhibiliha, boima bo phahameng, modulus e phahameng ea elastic, botsitso bo botle ba lik'hemik'hale le botsitso ba mocheso.Ho thatafala ha eona, ho hanyetsa le ho hanyetsa mocheso ho molemo haholo ho feta lisebelisoa tsa ho itšeha tsa HSS.

Boima: Sesebelisoa sa Carbide 89 ~ 94HRC.Lisebelisoa tsa HSS 62-70HRC.

Ho hanyetsa mocheso: Lisebelisoa tsa Carbide ho 800-1000 ℃, lisebelisoa tsa HSS ho 600-650 ℃.

Khanyetso ea ho roala: Ho hanyetsa ha lisebelisoa tsa Carbide ke makhetlo a 15-20 ho feta a lisebelisoa tsa HSS.

Lebelo la ho itšeha: Lebelo la sesebelisoa sa Carbide ke makhetlo a 4-10 ho feta a sesebelisoa sa HSS.

2. HSS milling cutters leCarbide milling cuttersho sebelisoa?

Ha se maemo ohle a ts'ebetso a hlokang ts'ebeliso ea li-cutters tsa Carbide, kaha taolo ea litšenyehelo ea ts'ebetso e 'ngoe le e' ngoe e fapana, 'me lisebelisoa tse fapaneng tsa ho itšeha li ka sebelisoa habonolo.

Ha boima ba machining bo le tlase, litlhoko tsa ho nepahala ha machining ha li phahame, 'me lisebelisoa tsa mochine o tlaase li sebelisoa, bongata ba lihlahisoa bo nyenyane,' me phaello e tlaase, lisebelisoa tsa ho itšeha tsa HSS li ka sebelisoa.Le bakeng sa lisebelisoa tse ling tse thata tsa mochini, lisebelisoa tsa HSS le tsona li ka ba le bokhoni, empa lebelo la tsona la ho itšeha, ho hanyetsa le ho tšoarella ha tsona ha lia lekana.

Ke nahana hore maemong a mangata, haholo-holo nakong ea machining a potlakileng, a sebetsang hantle le a maholo, ho hlokahala haholo ho sebelisa lisebelisoa tsa ho itšeha ka carbide, esita le lisebelisoa tsa ceramic le taemane: theko e phahameng ea sesebelisoa se le seng ha e bolele litšenyehelo tse phahameng tsa ho sebetsa. ;Maemong a mangata, ho sebelisa lisebelisoa "tse theko e phahameng" ho fella ka litšenyehelo tse tlase tsa ho sebetsa ho feta lisebelisoa tsa HSS.

Nako ea poso: Jun-03-2023