Hajoale, indasteri ea ts'ebetso ea mochini ea China e ntse e tsoela pele ka potlako, 'me lisebelisoa tse ling tseo ho leng thata ho li khaola li sebelisoa haholo indastering ea thepa le indastering ea mochini o nepahetseng.E le ho finyella litlhoko tsa nts'etsopele ea indasteri ea morao-rao ea ho sebetsana le mechine, re hloka ho sebelisa lisebelisoa tse ling tse nang le matla a phahameng le boima bo botle.Ka hona, lisebelisoa tse thata tsa lisebelisoa li sebelisoa butle-butle ho indasteri ea ho sebetsa ka mechine.Sengoliloeng sena se shebana le ts'ebeliso ea lisebelisoa tse thata tsa machining ka lebaka la nts'etsopele ea lisebelisoa tse thata, e le ho fana ka litšupiso tse kopanetsoeng bakeng sa metsoalle indastering e le 'ngoe.

Ka nts'etsopele e potlakileng ea theknoloji ea morao-rao ea tlhahiso le tlholisano e matla ea 'maraka, litlhoko tsa indasteri ea tlhahiso ea mochini bakeng sa likarolo tsa lisebelisoa tsa mochini le tsona lia eketseha, haholo-holo bakeng sa ts'ebetso ea sebopeho sa likarolo tsa mochini.Ka hona, lisebelisoa tse ncha tse nang le thepa e sa tšoaneng li hlahile butle-butle sechabeng.Lisebelisoa tsena tse ncha ha li fane feela ka phephetso e kholo ho lisebelisoa tsa khale tsa machining, empa hape li thata haholo ho li sebetsa.Ka nako ena, lisebelisoa tse tsoetseng pele tsa ho itšeha li fetohile senotlolo sa nts'etsopele ea indasteri ea ts'ebetso ea mochini, 'me ha ho pelaelo hore lisebelisoa tse thata tsa lisebelisoa li sebelisitsoe ts'ebetsong ea mehleng ea kajeno.

1. Histori ea nts'etsopele ea lisebelisoa tse thata

Lilemong tsa bo-1950, bo-rasaense ba Amerika ba ile ba nka daemane ea maiketsetso, bond, le boron carbide powder e le lisebelisoa tse tala, tse ileng tsa itšoara tlas'a mocheso o phahameng le khatello, le sintered polycrystalline block e le thepa e ka sehloohong ea sesebelisoa.Kamora lilemo tsa bo-1970, butle-butle batho ba ile ba qapa lipampiri tse kopantsoeng, tse hlahisoang ka ho kopanya daemane le carbide e entsoeng ka samente, kapa boron nitride le carbide e entsoeng ka samente.Ho theknoloji ena, carbide e entsoeng ka samente e nkoa e le substrate, 'me lera la daemane le thehoa holim'a substrate ka ho hatisa kapa ho sintering.Taemane e ka ba 0.5 ho 1 mm botenya.Lisebelisoa tse joalo li ke ke tsa ntlafatsa feela khanyetso ea ho kobeha ha thepa, empa hape le ho rarolla bothata ba hore lisebelisoa tsa setso ha li bonolo ho tjheseletsa.Sena se khothalelitse sesebelisoa sa thepa e thata ho kena sethaleng sa kopo.

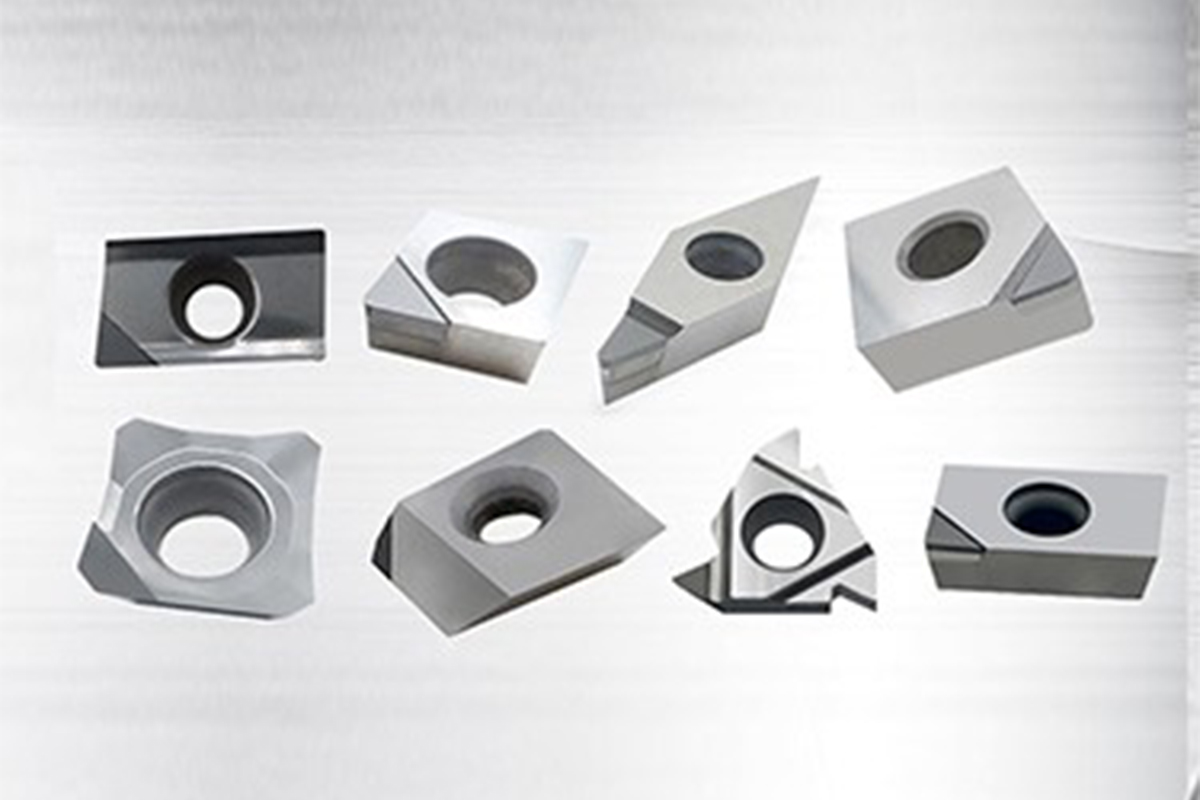

2. Tšebeliso ea lisebelisoa tse thata tsa lisebelisoa ho machining

(1) Tšebeliso ea lisebelisoa tsa daemane e le 'ngoe ea kristale

Taemane e le 'ngoe ea kristale hangata e arotsoe ka daemane ea maiketsetso le taemane ea tlhaho.Ka kakaretso, haeba daemane e le 'ngoe ea kristale e sebelisoa ho etsa sesebelisoa, hoa hlokahala ho khetha daemane e nang le boholo bo boholo ba likaroloana, boima bo fetang 0.1 g le bophara ba bophara bo fetang 3 mm.Hona joale, taemane ea tlhaho ke ntho e thata ka ho fetisisa ea liminerale.Ha e na feela ho hanyetsa ho apara hantle, empa hape sesebelisoa se entsoeng ka eona se bohale haholo.Ka nako e ts'oanang, e na le khanyetso e phahameng ea ho khomarela le conductivity e tlaase ea mocheso.Sesebelisoa se sebetsitsoeng se boreleli ebile se boleng bo botle.Ka nako e ts'oanang, sesebelisoa se entsoeng ka daemane ea tlhaho se na le nako e ntle haholo le bophelo bo bolelele ba tšebeletso.Ho phaella moo, ha u khaola nako e telele, e ke ke ea ama ts'ebetso ea likarolo.The e batlang e le tlaase mocheso conductivity ka ba le phello e ntle ho thibela deformation ea likarolo.

Taemane ea tlhaho e na le melemo e mengata.Le hoja melemo ena e theko e boima, e ka finyella litlhoko tsa mekhoa e mengata ea ho itšeha ka mokhoa o nepahetseng haholo 'me e sebelisoa haholo ho itšeha ka mokhoa o nepahetseng le ho itšeha ka mokhoa o hlakileng.Joalo ka liipone tse bonts'ang tse sebelisang li-reactor tsa athomo le mahlale a mang a tsoetseng pele, hammoho le li-gyroscope tsa ho tsamaea fatše tse sebelisoang ho limisaele kapa lirokete, hammoho le likarolo tse ling tsa oache, lisebelisoa tsa tšepe, joalo-joalo, li sebelisitse theknoloji ena.

(2) Tšebeliso ea lisebelisoa tsa daemane tsa polycrystalline

Polycrystalline diamond hangata e bitsoa sintered diamond.Tšebeliso ea daemane ea polycrystalline bakeng sa litšepe tse kang cobalt, ka mocheso o phahameng le maemo a khatello e phahameng, e tla etsa hore daemane e ngata e le 'ngoe ea kristale ea phofo ea polycrystalline e be e le' ngoe, kahoo e etsa lisebelisoa tsa lisebelisoa tsa polycrystalline.Boima ba daemane ea polycrystalline bo tlase ho feta taemane ea tlhaho.Leha ho le joalo, e entsoe ka mefuta e sa tšoaneng ea phofo ea daemane, 'me ha ho na taba ea hore lifofane tse fapaneng tsa kristale li na le matla a fapaneng le boima.Ha u itšeha, moeli oa ho itšeha o entsoeng ka daemane ea polycrystalline o na le khanyetso e phahameng haholo ea tšenyo ea kotsi le ho hanyetsa ho apara hantle.E ka boloka moeli o sehang o le bohale ka nako e telele.Ka nako e ts'oanang, e ka sebelisa lebelo le batlang le potlakile ha le etsa machining.Ha ho bapisoa le lisebelisoa tsa carbide tse entsoeng ka samente ea WC, lisebelisoa tsa taemane tsa polycrystalline li na le bophelo bo bolelele ba ts'ebeletso, phihlello e bonolo ea thepa ea maiketsetso le litheko tse tlase.

(3) Tšebeliso ea daemane ea CVD

Thepa ea lisebelisoa tsa daemane ea CVD e sebetsoa tlas'a khatello e tlase, e leng phapang e kholo ho tloha ho theknoloji ea setso ea PSC le theknoloji ea PDC.Taemane ea CVD ha e na karolo ea catalyst.Le hoja e tšoana le daemane ea tlhaho libakeng tse ling, e ntse e tšoana le daemane ea polycrystalline ka thepa, ke hore, lithollo tsa motsoako li hlophisoa ka mokhoa o sa laoleheng, ho haella ha brittle cleavage surface, 'me li na le thepa e tšoanang pakeng tsa bokaholimo.Ha ho bapisoa le lisebelisoa tse entsoeng ke theknoloji ea setso, lisebelisoa tse entsoeng ke theknoloji ea daemane ea CVD li na le melemo e mengata, e kang sebōpeho sa sesebelisoa se rarahaneng, theko e tlaase ea tlhahiso, le mahare a mangata a lehare le le leng.

(4) Tšebeliso ea polycrystalline cubic boron nitride

Polycrystalline cubic boron nitride (PCBN) ke sesebelisoa se thata se atileng haholo, se sebelisoang haholo machining.Sesebelisoa se entsoeng ka theknoloji ena se na le thata e babatsehang le ho hanyetsa ho roala.E ke ke ea sebelisoa feela ka mocheso o batlang o le holimo, empa hape e na le khanyetso e ntle ea kutu le conductivity ea mocheso.Ha ho bapisoa le lisebelisoa tsa PCD le PDC, lithulusi tsa polycrystalline cubic boron nitride li ntse li le tlase ka ho hanyetsa ho apara, empa li ka sebelisoa ka tloaelo ho 1200 ℃ 'me li ka mamella ho bola ha lik'hemik'hale tse itseng!

Hajoale, polycrystalline cubic boron nitride e sebelisoa haholo tlhahisong ea likoloi, joalo ka lienjine tsa makoloi, li-transmission shafts, le brake discs.Ho feta moo, hoo e ka bang karolo ea bohlano ea lisebelisoa tse boima tsa lisebelisoa le tsona li sebelisa theknoloji ena.Lilemong tsa morao tjena, ka tsoelo-pele ea theknoloji ea k'homphieutha le theknoloji ea mochine oa CNC, tšebeliso ea polycrystalline cubic boron nitride e se e atile ka ho eketsehileng, 'me ka ts'ebetsong ea likhopolo tse tsoetseng pele tsa machining tse kang ho itšeha ka lebelo le phahameng, ho reteleha ho e-na le ho sila, sesebelisoa. thepa ea polycrystalline cubic boron nitride butle-butle e tsoetse pele ho ba sesebelisoa sa bohlokoa ts'ebetsong ea sejoale-joale ea ho fetola.

3. Kakaretso

Ts'ebeliso ea lisebelisoa tse thata tsa machining ha e ntlafatse boleng le ts'ebetso ea machining feela, empa hape e phetha karolo ea bohlokoa ho nts'etsopele ea indasteri ea ts'ebetso ea mochini.Ka hona, e le ho khothaletsa nts'etsopele ea indasteri ea ts'ebetso ea mechini, hoa hlokahala ho tsoela pele ho matlafatsa lipatlisiso tsa lisebelisoa tse thata, ho utloisisa ka botlalo tsebo e amanang le lisebelisoa tse thata, le ho matlafatsa ts'ebetso ea kopo, eseng feela ho ntlafatsa boleng ba lisebelisoa. basebetsi, empa hape le ho matlafatsa ts'ebeliso ea mahlale le thekenoloji ho ntlafatsa lisebelisoa tse thata, e le ho hlokomela nts'etsopele ea leapfrog ea indasteri ea ts'ebetso ea mochini.

Nako ea poso: Jun-03-2019