Carbide Step Drill Bakeng sa tšepe e sa hloekang le Aluminium

Sesebelisoa sa sehlahisoa

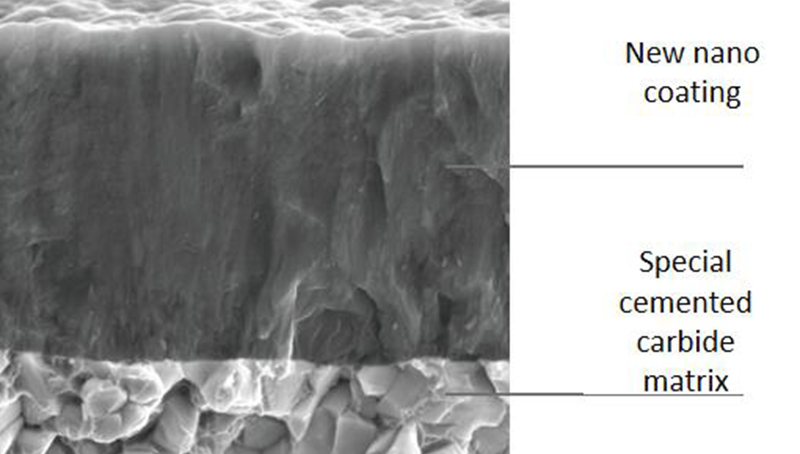

Ho khomarela hantle pakeng tsa ho roala le substrate ho netefatsa botsitso ba ts'ebetso le ho lelefatsa bophelo ba lisebelisoa

Boreleli ba ho roala holim'a metsi bo fokotsa khanyetso ea ho itšeha le ho ntlafatsa khanyetso ea ho roala lisebelisoa

E loketse: Tšepe, tšepe e sa hloekang, aluminium, tšepe e entsoeng ka tšepe le tšepe e thata e phahameng, E sebelisoa haholo sebakeng sa sefofane, ho etsa likoloi, ho etsa mehala ea thekeng, ho paka li-chip le liindasteri tse ling.

Melemo ea lihlahisoa

OPT e fapane: ke pula-maliboho ho tsa theknoloji le boqapi ka lilemo tse fetang 25.

Seaparo se sebelisoang ke OPT ke 40% se matla ho feta seaparo se tloaelehileng.

Theknoloji e ncha ea ho roala "nanostructure" e amoheloa, 'me sebopeho sa ho roala se kopane.

Ho khomarela hantle pakeng tsa ho roala le substrate ho netefatsa botsitso ba ts'ebetso le ho lelefatsa bophelo ba lisebelisoa.

Boreleli ba ho roala holim'a metsi bo fokotsa khanyetso ea ho itšeha le ho ntlafatsa khanyetso ea ho roala lisebelisoa.

Tšebeliso ea lisebelisoa tsa rona tsa ho itšeha indastering ea litebelo

Lithako tsa rona tsa ho cheka li etselitsoe ka ho khetheha ho monya litšusumetso tse matla.

Linomoro lia ipuella.Ha re ne re lekoa tlas'a maemo a tšoanang, likarolo tsa rona li ile tsa phela ho feta tsa lik'hamphani tse ling ka ho feta 30%.

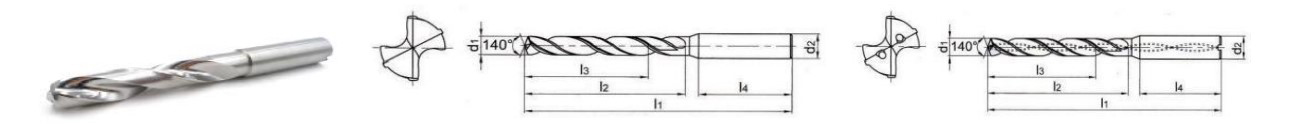

1.Tlhaloso ea karoloana ea carbide e bonolo ho phunyeha

2. Ntlha e phunyeletsoa ka tšepe ea tšepe ea tungsten e matlafalitsoeng

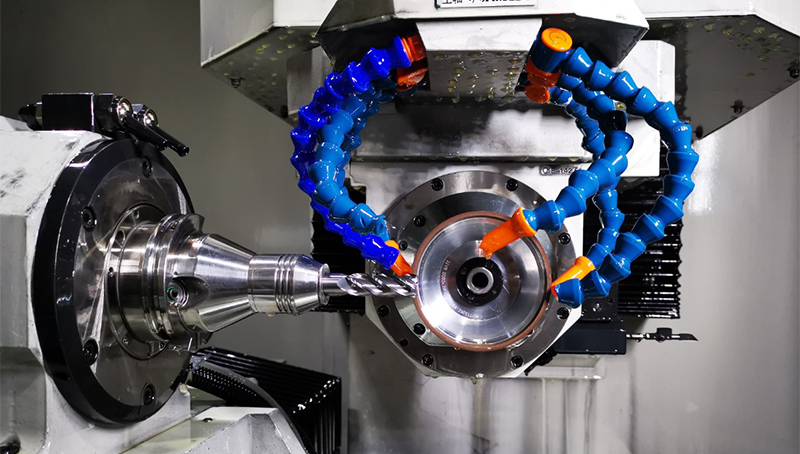

U ka sebelisa lisebelisoa tsa kopo tse ntlafalitsoeng ka ho khetheha tse sebelisoang ke litsebi tse koetlisitsoeng

Theknoloji e bolelle litsebi tsa hau tsa tlhahiso.U ka boela ua re bolella litlhoko tsa hau, k'hamphani ea rona ho u fa tharollo e felletseng

Ho sebetsana hantle le li-groove

Mokhoa o phahameng oa ho sebetsa ka mokhoa o nepahetseng o sebelisetsoa ho tšoara qetello ea groove le chute ea tšepe, e fokotsang ho itšeha ha motsoako oa alloy mme e ka ntša chute ea tšepe ka potlako, kahoo e fokotsa mocheso oa sesebelisoa le ho ntlafatsa bophelo ba lesela.

Tiisetso e sa tshwenyeheng ya bophelo bohle

Haeba sesebelisoa sa hau se thata sa alloy se hloka ho sila, u ka boela ua re fumana ho sila, ka nako e ts'oanang bakeng sa lisebelisoa tsa rona li tla fana ka ts'ebeletso ea morao-rao ea thekiso, ho na le mathata a lisebelisoa kapa mathata a tlhahiso, re tla ba tšebeletso ea lihora tse 24 le ho rarolla!

Re moetsi oa seha se hloahloa sa tloaelo

Tungsten carbide bur PROCESS PROCESS

Mohato oa 1: Sebelisa lisebelisoa tsa boleng bo holimo

Mohato oa 2: Ho sila profil

Thepa ea rona ea tlhahiso ea lisebelisoa tsa tlhahiso ea lihlahisoa tsa mochini oa tungsten tšepe CNC mochini o silang, mochini o silang oa pompo, mochini o silang oa CNC oa mochini o silang le mochini o silang, ehlile, ho na le mefuta e fapaneng ea meralo ea litsebi le basebetsi ba tlhahiso.

| Bit bophara sebaka d1(m7) | Karolelano ea botebo ba ho cheka (1/d) | Mokhoa oa ho pholisa | Sebopeho sa Shank | Mokhoa oa ho odara | Litekanyo tsa mantlha(mm) | litlhaloso | ||||

| Shank bophara | Kakaretso bolelele | Sekotjana bolelele | E khothalelitsoe botebo ba ho cheka | ho roala | ||||||

| d2(h6) | 11 | 12 | 13 | |||||||

| 2 ~ 2.5 | 3 | Pholiso ea kantle | Shank e otlolohileng | d113*d2*11*3D | 3 | 58 | 13 | 9 | ||

| 5 | Pholiso ea kantle | Shank e otlolohileng | d1*13*d2*l1*5D | 3 | 58 | 18 | 14 | |||

| 2.55~2,95 | 3 | Pholiso ea kantle | Shank e otlolohileng | d113*d2*11*3D | 4 | 58 | 13 | 9 | ||

| 5 | Pholiso ea kantle | Shank e otlolohileng | d1*13*d2*11*5D | 4 | 58 | 18 | 14 | |||

| 3~3.5 | 3 | Pholiso ea kantle | Shank e otlolohileng | d1*13*d2*11*3D | 4 | 62 | 20 | 14 | ||

| 5 | Pholiso ea kantle | Shank e otlolohileng | d1*13*d2*11*5D | 4 | 66 | 28 | 23 | |||

| 3.6~4 | 3 | Pholiso ea kantle | Shank e otlolohileng | d1*13*d2*11*3D | 4 | 58 | 20 | 14 | ||

| 5 | Pholiso ea kantle | Shank e otlolohileng | d113*d2*11*5D | 4 | 66 | 28 | 23 | |||

| 8 | Phodiso ya ka hare | Shank e otlolohileng | d1*13*d2*l1*8D | 4 | 72 | 34 | 29 | |||

| 4 ~ 4.9 | 3 | Pholiso ea kantle | Shank e otlolohileng | d113*d2*11*3D | 5 | 66 | 24 | 17 | ||

| 5 | Pholiso ea kantle | Shank e otlolohileng | d1*3*d2*11*5D | 5 | 74 | 34 | 26 | |||

| 8 | Phodiso ya ka hare | Shank e otlolohileng | d113*d2*11*8D-C | 6 | 95 | 57 | 46 | |||

| 5~6.0 | 3 | Pholiso ea kantle | Shank e otlolohileng | d1*13*d2*11*3D | 6 | 66 | 28 | 20 | ||

| 5 | Pholiso ea kantle | Shank e otlolohileng | d1*13*d2*11*5D | 6 | 82 | 42 | 32 | |||

| 8 | Phodiso ya ka hare | Shank e otlolohileng | d1*13*d2*I1*8D-C | 6 | 95 | 57 | 47 | |||

Tafole e sebetsang ea lisebelisoa tse entsoeng

| palo | Lisebelisoa tse entsoeng | |||||||||

| Tšepe e bonolo HB≤ 180 | Khabone le motsoako litšepe | Tšepe e thata pele, tšepe e thata | ts'epe e sa beng le mabali | tšepe ea tšepe | Tšepe ea ductile | motsoako oa aluminium | mocheso- ho hanyetsa kaofela | |||

| ~ 40HRC | ~ 50HRC | ~ 60HRC | ||||||||

Maikutlo:

1.Haeba 3 kapa 5 times drill bit e hloka ho pholile ka hare, ka kopo, ngola molaetsa ha o laela, o lateloa ke C;

2.The handle is straight by default.If u hloka tse ling tse sebetsana maemo a, ka kopo, sheba rona sebetsana thepa kapa litšoantšo bakeng sa netefatso;3.Sekhutlo sa kamehla sa holimo ke likhato tse 140.Haeba ho hlokahala li-angles tse ling, ka kopo tšoaea kapa u shebe setšoantšo;

4.Haeba litekanyetso tsa odara li sa lumellane le tsa k'hamphani ea rona, u ka tsebisa basebeletsi ba rona ba litšebeletso tsa bareki, 'me re tla thabela ho u fa litšoantšo bakeng sa netefatso;

5. Sehahi ha se koaheloe ke kamehla.Haeba ho hlokahala ho roala, ka kopo tsebisa litlhoko tsa hau kapa lisebelisoa tse sebetsitsoeng.